For over 30 years, MERTELLS INDUSTRIAL has been offering predictive and preventive maintenance service contracts for process instrumentation, process gas chromatographs, and process analyzers:

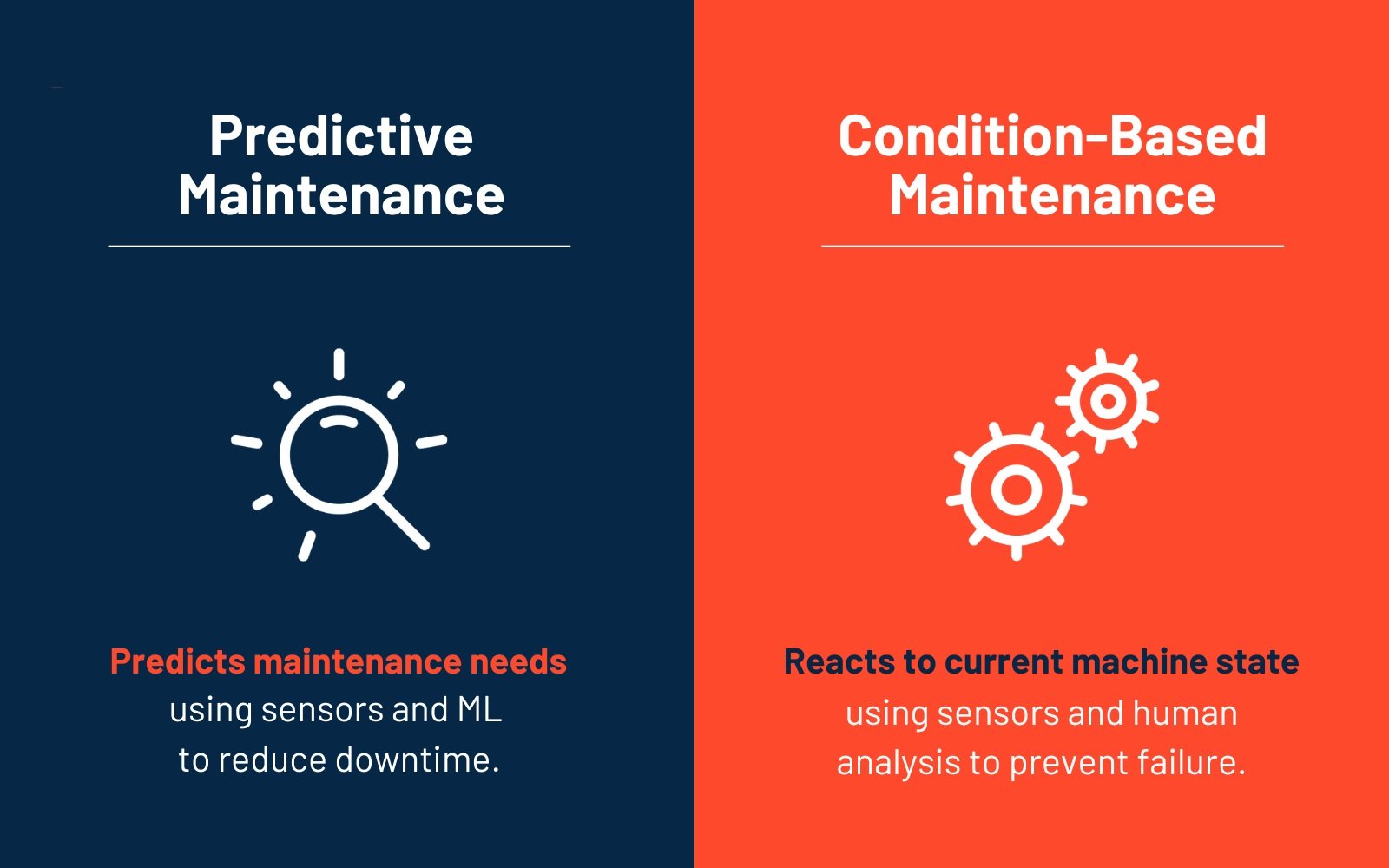

Predictive Maintenance:

- Objective: Predictive maintenance aims to anticipate equipment failures before they occur, minimizing downtime and maximizing efficiency.

- Services:

- Condition Monitoring: Regularly monitoring critical parameters (e.g., temperature, pressure, vibration) to detect deviations from normal behavior.

- Data Analytics: Leveraging historical data and machine learning algorithms to predict potential issues.

- Benefits:

- Cost Savings: By addressing issues proactively, you avoid costly emergency repairs.

- Increased Uptime: Equipment stays operational, reducing production interruptions.

- Optimized Maintenance Schedules: Targeted maintenance based on actual needs.

Preventive Maintenance:

- Objective: Preventive maintenance focuses on scheduled tasks to keep equipment in optimal condition.

- Services:

- Regular Inspections: Scheduled visits by technicians to inspect, clean, and calibrate instruments.

- Component Replacement: Replacing worn parts (e.g., seals, filters) to prevent failures.

- Benefits:

- Longer Lifespan: Regular care extends the life of your equipment.

- Consistent Performance: Prevents gradual deterioration.

- Compliance: Ensures adherence to safety and regulatory standards.

Statistical Performance Reports:

- Content:

- Performance Metrics: Quantitative data on instrument performance (e.g., accuracy, precision, response time).

- Trends: Identifying patterns over time (e.g., drift, stability).

- Threshold Alerts: Highlighting deviations from acceptable ranges.

- Purpose: These reports empower informed decision-making and guide maintenance efforts.

- Maintenance Recommendations:

- Tailored Advice: Based on statistical reports and actual performance data.

- Prioritization: Recommending urgent vs. routine maintenance tasks.

- Optimization: Suggesting adjustments to enhance efficiency.

- Content:

Our contracts, include periodic site visits, and 24/7 Online support, as well as remote monitoring and maintenance of devices under contract.

In summary, these service contracts combine proactive monitoring, scheduled maintenance, and data-driven insights to ensure your critical instruments operate reliably and efficiently. Trust our expertise to keep your processes running smoothly!