MERTELLS provides solutions based on gas chromatographs delivering dependable and accurate process analyses, featuring touch screen functionality for straightforward results. The chromatograph configurations, visual displays, and data are distinctly organized for ease of comprehension and upkeep. Since 1976, MERTELLS has been providing GC solutions to the oil & gas, refining, and petrochemical sectors globally.

Description

Mertells Industrial helps to design and commercialize advanced process gas chromatograph solutions, specializing in Valmet Maxum II gas chromatographs and Envent process analyzers. Our tailored solutions ensure precise and reliable analysis for optimal performance in various industrial applications.

Valmet Maxum II Gas Chromatograph

Flexibility: Capable of analyzing both liquid and gaseous samples, making it suitable for a wide range of applications in refineries, oil refining, and chemical industries.

Reliability: Designed for precise operation even in harsh environments, ensuring consistent and accurate results.

Plug-and-Play Design: Simplifies maintenance and reduces downtime with easy-to-replace components.

Redundant Communication Options: Ensures secure communication with the plant’s control system.

Versatile Features: Includes a variety of injectors, ovens, detectors, and separation columns for optimal analytical results at low operating costs.

Modular Oven Configuration: Offers simple and reliable performance with removable analytical modules, reducing maintenance costs.

Intelligent Electronics: Provides user-friendly operation with local and central workstation control.

Envent’s 131S and 132S Gas Chromatographs

The Envent’s Gas Chromatographs are specifically designed for BTU measurement at the Oil & Gas industry. They offer high performance with the following features and benefits:

High-Performance GC Columns: Packed in the Envent GC Lab for efficient analysis.

Reduced Carrier Usage: Efficient column design minimizes carrier gas consumption.

Field-Serviceability: Easy access to electronics and GC components for quick maintenance.

Versatile Applications: Suitable for natural gas, gas processing, energy measurement, pipeline monitoring, and more.

Advanced Electronics: Non-incendive circuit design approved for Class I Division 1 areas, simplifying troubleshooting.

Comprehensive Software: Includes Envent Gas Chromatograph Software (GCS) for data storage and analysis.

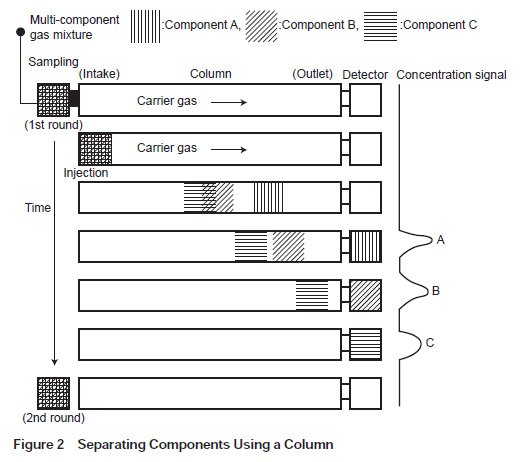

The separation process within the column involves the sample’s components moving with the carrier gas, dissolving into and emerging from the stationary phase at a rate determined by a specific partition coefficient for each component. This coefficient is the ratio of a component’s concentration in the stationary phase to that in the mobile phase when in equilibrium. The separation process results in the isolation of individual components over time.

Gas chromatography is an analytical method that involves the classification and separation of components within a gas or volatile liquid.

Types of Gas Chromatography Based on Separation Mechanism:

- Adsorption Chromatography: This method separates components based on their varying levels of adsorption to the stationary phase. Common stationary phases include materials like activated carbon, synthetic zeolite, and silica gel. It’s typically used for separating inorganic gases such as hydrogen (H2), nitrogen (N2), and carbon dioxide (CO2), as well as low-boiling-point hydrocarbons like methane (CH4), ethane (C2), and propane (C3).

- Partition Chromatography: This technique differentiates components based on their solubility in the stationary phase. High-boiling-point liquids, both non-polar and polar, are used as the stationary phase, which is coated on porous materials or the inner walls of the column. It’s mainly applied to separate organic substances with four or more carbon atoms, including hydrocarbons, alcohols, and organic acids.

Classification Based on Column Type:

- Open Tubular Column: An open tubular column is a hollow column with an inner coating of either powder or liquid stationary phase. These columns have an inner diameter ranging from 0.25 to 0.53 mm and are made from materials like fused silica or stainless steel with an inert coating. They can be tens of meters long and offer superior separation performance compared to packed columns.

- Packed Column: A packed column is filled with a powdered stationary phase. In process gas chromatography, these columns are often made of stainless steel with an inner diameter of 1 to 2 mm and are several meters long. The variety of packing materials available provides numerous options for tailoring separation characteristics.